The typical weight capacity range is between 500kg and 2,000kg (1,100 lbs to 4,600 lbs), with plastic pallets typically maxing out at around 1,000 kg (2,200 lbs) of weight capacity and wood pallets being able to hold up to 2,000kg (4,600 lbs). The weight each pallet can support depends on the type of material it is made of (wood, plastic, metal) and its dimensions. The height of the pallet itself is usually around 144 mm., but there might be differences. Standard pallet sizes and their dimensions Pallet Type If you are using a pallet that is not listed below, and you know the exact dimensions and maximum load capacity, then it is best to specify them using our pallet calculator's "Custom" option. There are many standard pallet sizes - the table bellow contains only the ones available for use in this tool, which are also the most commonly used ones. Below is a reference list of the standard sizes supported in our pallet calculator. If you know the maximum allowed weight of the pallet, then enter the weight of the item and we will calculate the total cargo weight and warn you if it is more than the allowed. Complex ordering results in some cases in fitting slightly more items onto the pallet, however it is also more difficult to follow a complex stacking scheme, leading to increased loading and unloading times, and probably higher costs for palletizing.įor your convenience we have pre-entered many of the most widely used pallet sizes in international shipping and logistics, meaning you don't need to enter their dimensions each time.

Currently it supports only simple item stacking, meaning that each item will be placed with the same orientation with regards to the base - no complex rotations or ordering.

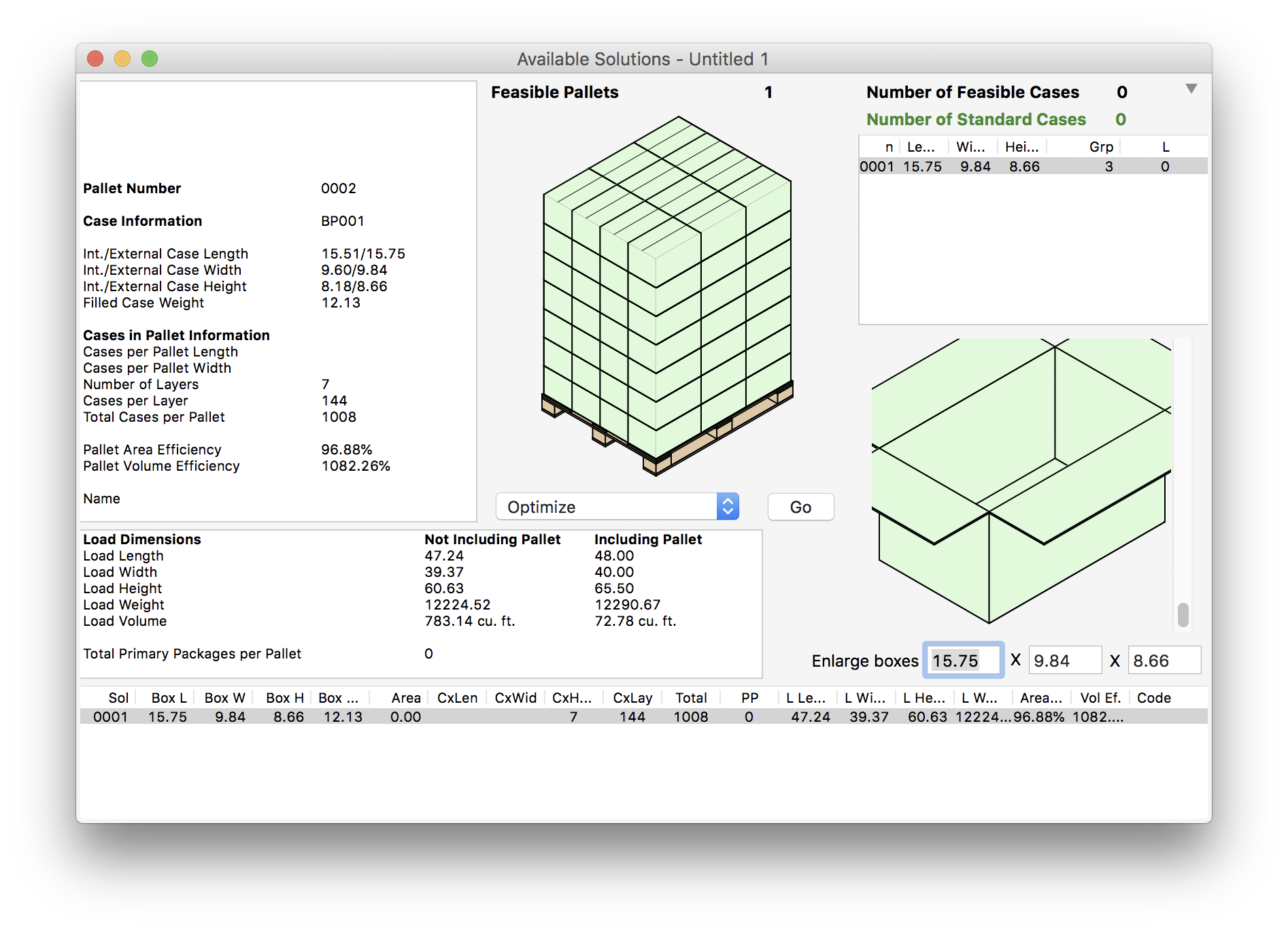

This is a pallet loading calculator that allows you to calculate how many items of the same dimensions and weight (optional) you can stack on a single pallet. Indeed, at times it can seem a bit too detailed.

To sum up, this tool is a very detailed resource for anyone dealing in product storage and transportation. A strong solution for product stacking problems Grouping similar items together does improve the situation, up to a point. There are plenty of informative fields and boxes, which can at times distract the attention. The interface may seem quite full, at first glance. However, this option comes at a price, since output files will be considerably larger in size! This can be very important, since losing details from pictures can severely affect the optimization process. Since the product generates images, a “Save images in high resolution” option is available. The program features multiple options for disseminating the results. Together with the actual products, this means that virtually all relevant factors affecting the efficiency of items storage and transportation are covered! Sharing analysis results is easily done The application allows users to create and customize their own containers and boxes. This is great when working with recurring and highly specific items!īut that's not all. If, however, this is not enough, there is always a “Define new product” option. Not only that, but the application features eight predefined categories, including cement sacks, milk boxes or horizontal cylinders.īetween them, these options should cover all imaginable needs.

#Pallet stacking software software

The software comes with two types of containers: cylinder and rectangular, but the length, width and height can be customized. A comprehensive resource for determining optimum storage patterns The application features multiple configurations which can be tweaked to suit almost any needs imaginable. PalletStacking is designed to aid users in optimizing packet arrangement.

0 kommentar(er)

0 kommentar(er)